Long-Term Reliability of Hydraulic Testing Equipment

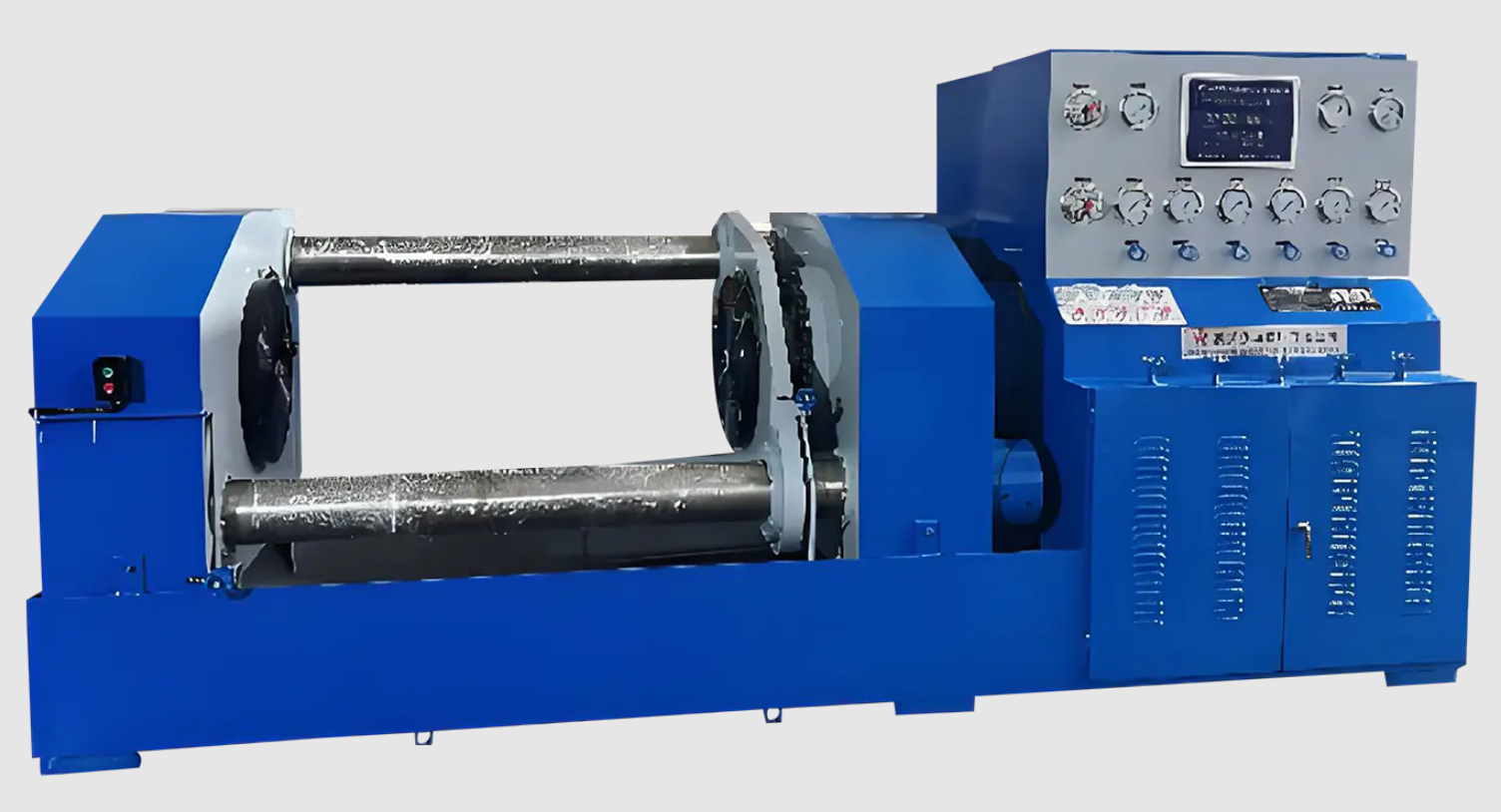

Valve Test Bench Machine, Ball Valve Test Bench are integral to quality assurance and testing processes for industrial valves. Zhejiang Duojia Hydraulic Co., Ltd. provides machines that allow controlled evaluation of valve performance under operational conditions. Their designs focus on accuracy, adaptability, and safe operation to support production, maintenance, and laboratory workflows.

Integration into production lines begins with planning the layout and positioning of the machine. Workflows are organized to allow efficient mounting, testing, and removal of valves. Adjustable fixtures accommodate different valve sizes without requiring frequent machine modifications. This flexibility ensures that testing can occur efficiently alongside ongoing manufacturing processes.

Ball valve test bench systems are equipped with hydraulic or pneumatic actuators that simulate real operational forces. Sensors record critical parameters such as pressure, flow, and potential leakage. Data acquisition systems log this information for analysis, enabling engineers to verify performance, identify potential defects, and make informed adjustments to valve design or production procedures.

Usage for quality assurance emphasizes repeatable and documented testing. Repeated actuation cycles provide information on wear, seal performance, and operational consistency. Digital interfaces allow operators to set automated sequences and record results, ensuring traceability and alignment with technical standards. Zhejiang Duojia Hydraulic Co., Ltd. machines are designed to support these processes while minimizing operator intervention.

Long-term reliability of hydraulic testing equipment depends on regular maintenance and inspection. Critical components, including actuators, sensors, and hydraulic systems, are positioned for easy access. Routine calibration ensures accuracy, and preventive maintenance reduces the risk of unexpected downtime. The machine’s design supports continuous operation in industrial environments without sacrificing measurement precision.

Operational safety is emphasized in the design. Protective barriers, emergency stop functions, and ergonomic adjustments minimize risk during high-pressure testing. These considerations allow operators to perform testing efficiently while maintaining consistent oversight and safety.

The combination of adaptable design, precise control, and data logging allows valve test bench machines to serve multiple functions, from production verification to research applications. Ball valve test benches specifically allow evaluation of rotational and sealing characteristics critical for functional reliability in pipeline systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness