Enhancing Safety with Composite Workwear Fabrics

Introduction to Fireproof Workwear Fabric

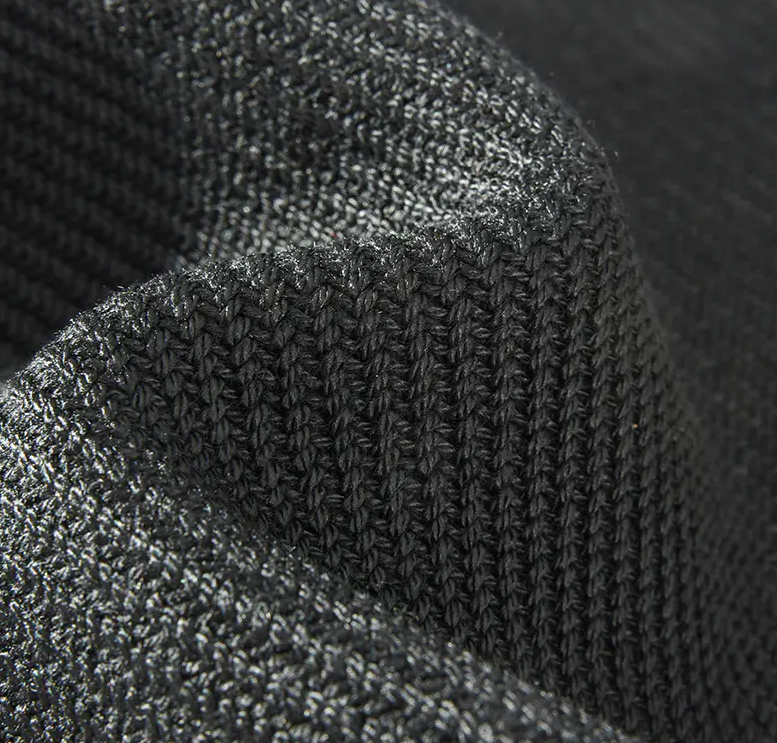

Fireproof Workwear Fabric is widely used in industrial and professional settings to protect workers from heat, sparks, and open flames. While fire resistance is the primary function, modern work environments often require additional protective properties, such as water resistance, chemical repellency, and anti-static performance. Combining fireproof fabrics with other functional materials can enhance overall safety and comfort, but the process involves careful selection and engineering to maintain each property without compromising fire-resistant capabilities.

Compatibility with Water-Resistant Fabrics

One common enhancement is adding water-resistant or waterproof layers to fireproof workwear. Lamination or coating techniques can bond fireproof fabric with a water-repellent layer, creating garments that protect against both flames and moisture. However, care must be taken to ensure that the coating does not interfere with the fabric’s breathability or thermal regulation. Additionally, the lamination process should not involve high temperatures that could weaken the fireproof fibers. When properly engineered, such composite fabrics provide dual protection, making them ideal for outdoor or harsh-weather work environments.

Integration with Anti-Static Materials

Anti-static properties are crucial in industries such as electronics manufacturing, petrochemical processing, and environments with flammable vapors. Fireproof workwear can be combined with conductive fibers or surface treatments that dissipate static electricity. Blending anti-static fibers into the weave or applying specialized coatings ensures that garments remain safe without altering the core fire-resistant structure. Designers must balance the proportion of conductive fibers to maintain flexibility and comfort while meeting regulatory safety standards.

Challenges in Fabric Compositing

While combining fireproof fabrics with other functional layers offers benefits, it also introduces challenges. Different materials may have conflicting physical properties, such as shrinkage rates, stiffness, or thermal tolerance. Improper bonding or lamination can reduce the effectiveness of one or more protective functions. Additionally, multi-layer composites may increase weight or reduce comfort, which can affect worker compliance and mobility. Engineers often perform rigorous testing to ensure that the final garment meets fire resistance standards (e.g., NFPA 2112 or EN ISO 11612) while incorporating additional protections.

Practical Applications and Benefits

Composite fireproof fabrics are widely used in firefighting gear, chemical plant uniforms, and outdoor industrial workwear. Firefighters, for example, benefit from garments that are both flame-resistant and water-repellent, keeping them safe during exposure to fire and water simultaneously. Petrochemical workers require anti-static, fireproof fabrics to prevent sparks in volatile environments. By combining multiple functional properties, manufacturers can produce garments that meet complex safety requirements without requiring multiple separate layers, simplifying workwear and improving usability.

Fireproof Workwear Fabric can indeed be combined with other functional materials, such as waterproof or anti-static fabrics, to create composite garments that address diverse industrial safety challenges. Successful integration requires careful material selection, engineering, and testing to ensure that fire resistance is maintained while adding new protective features. When executed properly, these composite fabrics provide enhanced safety, comfort, and versatility, making them essential for modern work environments that demand multiple layers of protection in a single garment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness