How Cbbmachine Supports Packaging Industry Efficiency

Cbbmachine: Precision Engineering for Industrial Machinery Needs

Cbbmachine is a trusted name in the field of industrial machinery, offering a diverse portfolio of equipment and mechanical components designed to support precision, durability, and efficiency in modern manufacturing. As industries continue to embrace automation and streamlined production processes, the demand for dependable machines and mechanical parts like those provided by Cbbmachine continues to grow.

The global manufacturing landscape is evolving rapidly, driven by increasing demand for product customization, faster lead times, and higher quality standards. In this dynamic environment, selecting reliable machinery is critical to long-term success. Cbbmachine serves this need by supplying solutions tailored to meet industry-specific challenges. Whether it's winding machinery, web guiding equipment, or various rollers and shafts, Cbbmachine’s product lineup is designed to enhance performance and reduce operational downtime.

A Versatile Range of Industrial Solutions

Cbbmachine offers a wide selection of mechanical components and automation accessories that contribute to process control and material handling efficiency. These products include differential shafts, banana rollers, mechanical chucks, aluminum rollers, and web guiding systems—each engineered with a focus on consistent performance and minimal maintenance requirements.

1. Differential Shafts

Used in slitting and rewinding processes, differential shafts help maintain precise tension across multiple widths of material. They allow for independent roll movement, reducing material waste and enhancing output quality.

2. Banana Rollers

Banana rollers are critical in eliminating wrinkles and creases in web materials. Their curved design allows them to evenly distribute tension across delicate or stretchable films, ensuring smooth and uniform winding or processing.

3. Expandable Chucks and Air Shafts

These components are essential in core holding and web winding applications. With their robust design and high clamping force, they offer secure grip during high-speed operations, improving machine stability.

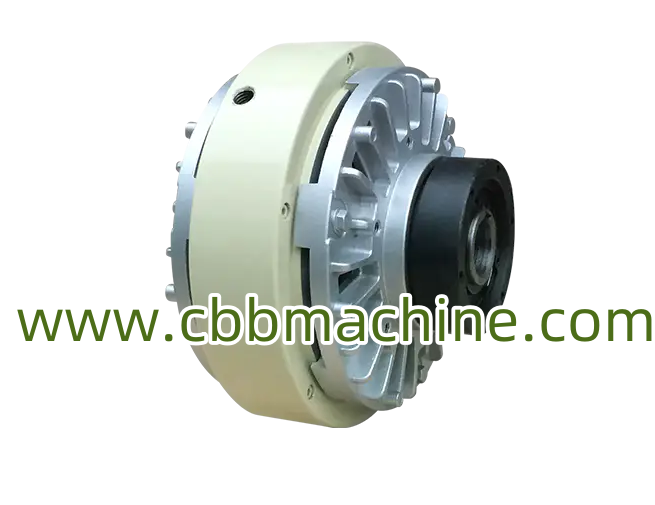

4. Magnetic Powder Clutches and Brakes

These parts provide smooth torque transmission and are especially useful in web tension control systems. Their quiet operation and fast response make them ideal for packaging, printing, and film converting industries.

5. Web Guide Systems

By detecting and correcting web misalignment in real-time, web guiding systems help avoid edge deviation issues, ensuring consistent product quality throughout the production run.

Quality and Customization as Core Values

Cbbmachine emphasizes quality craftsmanship and precision manufacturing throughout its production process. Each component is fabricated using strict quality control methods and modern machining technologies. In addition to standard models, Cbbmachine provides customized solutions tailored to fit specific machine sizes, production requirements, and application environments.

Customization options include different material compositions, surface finishes, dimensions, and mechanical properties. This level of flexibility allows clients to maintain process stability and equipment compatibility while addressing unique operational needs.

Serving Diverse Industries

Cbbmachine’s products are used in a broad spectrum of industries, including:

Packaging: Ensuring accurate winding and tension for flexible packaging materials.

Printing: Supporting clean feed and register control for high-speed printers.

Textile: Assisting in uniform tension and wrinkle elimination during fabric processing.

Plastic Film: Enhancing edge alignment and roll control during film extrusion and converting.

Labeling and Converting: Contributing to precise web handling and material slitting.

Each industry has its own demands and technical challenges. Cbbmachine’s comprehensive product lineup addresses these challenges through robust design, ease of integration, and user-friendly features.

Why Reliability Matters

In any production environment, equipment failure or inconsistency can lead to significant downtime and financial losses. Cbbmachine places strong emphasis on product reliability, focusing on components that require minimal maintenance while offering long-term performance. This commitment to quality helps clients reduce repair costs, limit production delays, and ensure greater continuity in manufacturing.

Moreover, by providing clear technical documentation and support, Cbbmachine makes the installation and operation process smoother for both engineers and operators.

Conclusion

As industrial demands continue to evolve, manufacturers need dependable partners for their machinery requirements. Cbbmachine offers a practical solution with a range of reliable, customizable, and easy-to-integrate mechanical components. By choosing high-quality engineering and thoughtful design, manufacturers can maintain efficiency, reduce errors, and meet the increasing expectations of today’s competitive markets.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness