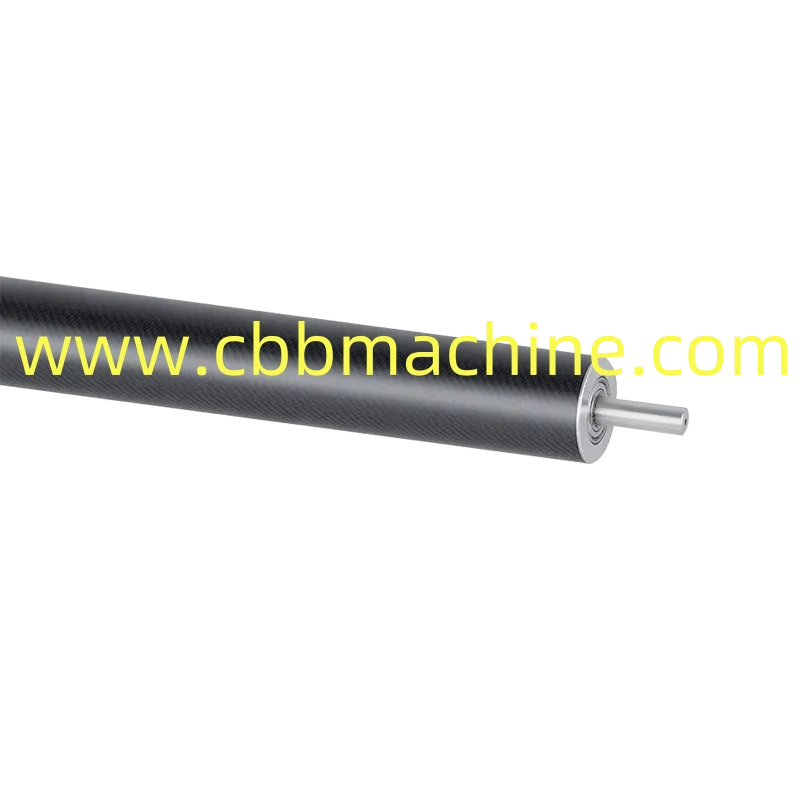

Precision Engineered CBBMACHINE Aluminum Roller for Smooth Web Control

Precision performance in high-speed machinery often depends on the quality and consistency of components like the Aluminum Roller , which plays a critical role in web guiding, tension control, and smooth material transportation.

Aluminum rollers are widely used in converting, printing, laminating, and packaging industries. Their popularity stems from a combination of light weight, corrosion resistance, and excellent machining properties. These characteristics ensure not only operational efficiency but also equipment longevity and reduced maintenance downtime.

The use of aluminum over steel provides a significant advantage in terms of rotational inertia. In systems where speed and response time matter, a lighter roller allows for quicker starts and stops, which is crucial in automated production lines. Lower inertia means less stress on motors and drive systems, translating into energy savings and longer component life.

Another advantage of aluminum rollers is their adaptability. They can be manufactured in a wide range of diameters, lengths, and surface finishes. Whether a customer requires a smooth surface for sensitive materials or a textured finish for grip, aluminum can be processed to meet exact specifications. Moreover, anodizing and coating options further enhance resistance to wear, chemical exposure, and heat.

When it comes to balancing, aluminum rollers offer excellent results. Precision dynamic balancing ensures that rollers rotate without causing vibration or material deviation, especially at high speeds. This precision contributes to consistent production quality, especially for materials like film, foil, and paper.

The application of aluminum rollers also reduces the weight burden on equipment frames, which is especially valuable in large-scale machinery. Reducing component weight leads to easier installation and less structural reinforcement, allowing for more flexible machine design and mobility.

For manufacturers looking to increase throughput without compromising precision, high-performance aluminum rollers are a strategic investment. In industries where micro-tolerances and stable web control are critical, choosing the right roller can influence the entire line’s productivity.

As the demand for efficiency and sustainability continues to grow, components like aluminum rollers will remain central to innovation in industrial manufacturing. Lightweight yet strong, versatile yet precise, they provide an ideal solution for today’s complex production environments.

To explore custom-engineered aluminum rollers designed for your application, please visit https://www.cbbmachine.com/product/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness