CBBMACHINE’s Guide to Choosing Your Differential Shaft Equipment

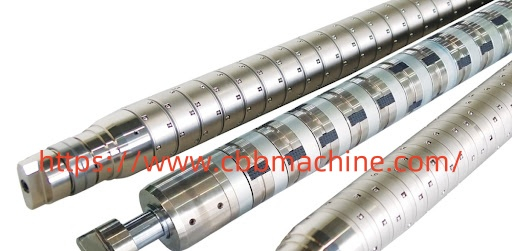

In advanced slitting and rewinding operations, precision is greatly enhanced when a Differential Air Shaft is incorporated into the process.

These shafts are designed to accommodate slight variations in web tension across multiple slit rolls, ensuring each roll winds evenly despite different thicknesses or materials. A consistent winding tension is essential in industries like film, foil, paper, and label production. Uneven winding can lead to telescoping, wrinkling, or slippage, resulting in production waste or rework. The implementation of differential shafts minimizes these issues, maintaining tight roll tolerances and optimizing output quality.

A major benefit of using this component is its automatic compensation for roll diameter differences. Unlike fixed shafts, the differential model utilizes internal friction elements or ball mechanisms that adjust independently for each core. This flexibility not only ensures consistent roll tightness but also allows for higher-speed operation without sacrificing performance.

Many manufacturers prefer this type of shaft due to its compatibility with both paper and plastic cores. In fast-paced industrial setups where frequent changeovers are required, differential shafts enable operators to quickly mount and dismount rolls. This significantly reduces machine downtime and improves productivity across the board.

Moreover, durability is another notable advantage. Most models are manufactured using hardened steel, aluminum, or a combination of materials that offer high load capacity and long-term service. With proper maintenance, a quality shaft can endure rigorous daily use without compromising on accuracy or functionality.

Choosing the right shaft depends on application needs—core size, material type, machine speed, and product tension range must all be considered. Whether in narrow web or wide web machinery, shaft adaptability can define the efficiency of the production process. As the manufacturing sector continues to demand higher performance and less waste, engineering solutions like these play a central role in maintaining competitive edge.

Operators also benefit from the enhanced ease of use. With no need for external tools or manual adjustments during winding, the learning curve is minimal, allowing teams to operate more efficiently. Additionally, because the shaft adapts to each roll’s specific characteristics, it contributes to less material stretching, improving the overall integrity of finished products.

In conclusion, the application of differential shafts is not merely a technical upgrade—it’s a strategic investment in productivity, quality, and operational efficiency. As industrial needs evolve, incorporating precise and flexible components becomes essential to long-term success.

To explore more about premium mechanical shafts and automation components, visit www.cbbmachine.com.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness