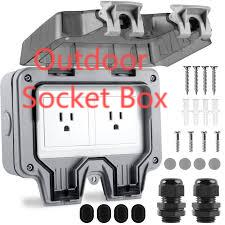

Electrical Outdoor Box Innovation By Nante For Smart, Durable Installations

In exposed installations, choosing the correct enclosure early prevents many field failures, because a properly specified Electrical Outdoor Box placed to shed water and avoid pooling protects circuits and components; likewise, careful selection of a Electrical Outdoor Box at the design stage reduces downtime, simplifies maintenance, and improves safety for technicians and end users. This article outlines material choices, protection ratings, practical design features, installation best practices, and forward-looking considerations so specifiers, contractors, and facility managers can select enclosures that perform reliably outdoors.

Materials and Corrosion Resistance

Material selection is the first line of defense against environmental degradation. UV-stable thermoplastics resist brittleness and color change under prolonged sun exposure, while aluminum and stainless steel provide superior mechanical strength and corrosion resistance in industrial or coastal environments. Consideration of fasteners, hinges, and gasket materials is crucial because these small parts often determine long-term sealing performance. Silicone and EPDM gaskets maintain compressibility across wide temperature ranges, preventing seal failures that let contaminants in. For aggressive atmospheres, specify marine-grade hardware and protective coatings to lengthen service life.

Ratings, Seals, and Thermal Strategies

Ingress Protection (IP) and impact resistance (IK) ratings give objective measures of an enclosure’s ability to resist dust, water, and physical abuse. For general outdoor service, IP65 is a common minimum; higher-exposure locations may require IP66 or better. IK ratings matter in public or high-traffic sites where accidental impacts occur. Enclosures that house heat-generating electronics also demand thermal planning: passive vents, heat-dissipating mounting plates, and internal spacing reduce hotspots and extend component life. Any ventilation or cooling approach must preserve the enclosure’s protective rating and avoid introducing contamination pathways.

Nante Practical Design Features That Save Time

Thoughtful design details speed installation and reduce callbacks. Look for removable mounting plates, captive screws that won’t fall into cavities, clear knockout patterns, and integrated gland plates for neat cable entry. Modular DIN-rail options and pre-drilled mounting bosses simplify internal layouts and future retrofits. Transparent inspection windows, tamper-resistant fasteners, and internal cable management bosses help maintain a clean sealing plane during maintenance. These practical features lower labor hours, improve safety during servicing, and keep the enclosure’s protective integrity intact over time.

Installation Best Practices for Longevity

Correct siting and mechanical mounting have outsized effects on performance. Mount enclosures on stable, vibration-free surfaces and orient cable entries to prevent direct runoff into seals. Use correctly sized cable glands and strain reliefs to prevent conductor fatigue and preserve the sealing plane. Avoid overtightening screws that can distort gaskets and compromise waterproofing. In climates prone to condensation, install breathable membranes or engineered vents that allow moisture escape without admitting dust. Establish a routine inspection schedule to check gaskets, fasteners, and seals so problems are caught early rather than after ingress has caused damage.

Applications, Modularity, and Future-Proof Planning

Outdoor enclosures serve many applications: landscape lighting and pool controls, solar combiner boxes, EV charging peripherals, and industrial motor starters. Modern projects increasingly demand space for surge protection, communications modules, and environmental sensors; plan for these by choosing deeper boxes or configurable interiors. Modular solutions let installers add DIN-mounted devices or gateways without swapping the entire cabinet. Future-ready specification reduces lifecycle costs and keeps infrastructure adaptable as technology and connectivity requirements evolve.

Selecting an enclosure is a systems decision that balances environment, heat load, mounting realities, and future expansion. Prioritize proven materials, appropriate IP/IK ratings, practical internal layouts, and proper installation technique to ensure equipment longevity and safety. For official specifications, certified test results, and configurable outdoor enclosure options, visit www.nante.com/product/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness