Industry Applications of Plastic Brightening Additives

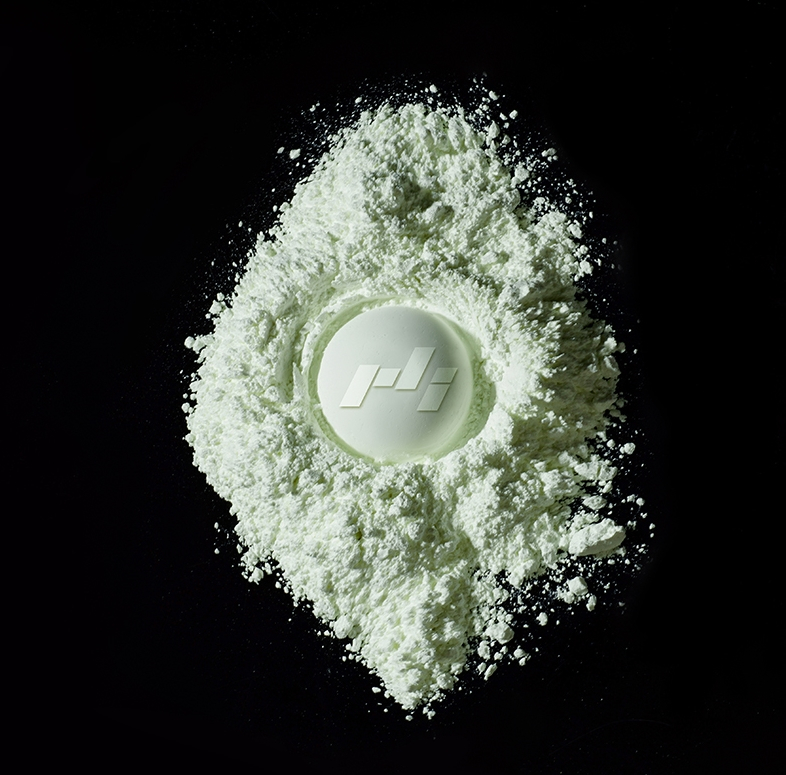

Optical Brightener for Plastic, Fluorescent Whitening Agents serve as key additives to enhance the whiteness and visual clarity of polymer products. Their proper incorporation relies on chemical compatibility, processing parameters, and attention to dispersion uniformity. Successful implementation produces a consistent and visually appealing product across multiple manufacturing runs.

Dispersion of optical brighteners is critical for even performance. Methods such as dry blending, masterbatch incorporation, and pre-dispersed concentrates are used to achieve homogeneous distribution. Poor dispersion can lead to streaks, spots, or inconsistent brightness, particularly in thin-walled or transparent components. Monitoring particle size, blending time, and melt flow contributes to uniform optical results.

Quality control includes verifying additive concentration, assessing whiteness indices, and testing for thermal stability. Samples are taken from production batches to evaluate brightness, emission efficiency, and compatibility with other additives or fillers. Adjustments in dosage or processing conditions are made to maintain performance consistency across different polymer formulations.

Fluorescent whitening agents are used in various industries, including packaging, automotive components, consumer goods, and technical plastics. In packaging, brighteners improve perceived cleanliness and shelf appeal. Automotive plastics benefit from uniform color and clarity in interior and exterior components. Consumer goods such as household containers, toys, and electronics utilize brighteners to maintain a visually appealing surface.

Environmental and regulatory factors influence additive selection. Agents must meet safety requirements for food contact or consumer exposure and be compatible with recycling processes. Awareness of these considerations ensures compliance while maintaining effective brightening performance in the finished product.

Optimizing brightener use involves balancing chemical, thermal, and processing considerations. Proper selection, controlled dispersion, and ongoing quality checks produce plastic products with consistent optical performance. Fluorescent whitening agents remain a key tool for manufacturers seeking improved aesthetics, long-term color stability, and enhanced visual appeal across diverse plastic applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness