Training Operators For Accurate Metal Cutting Results

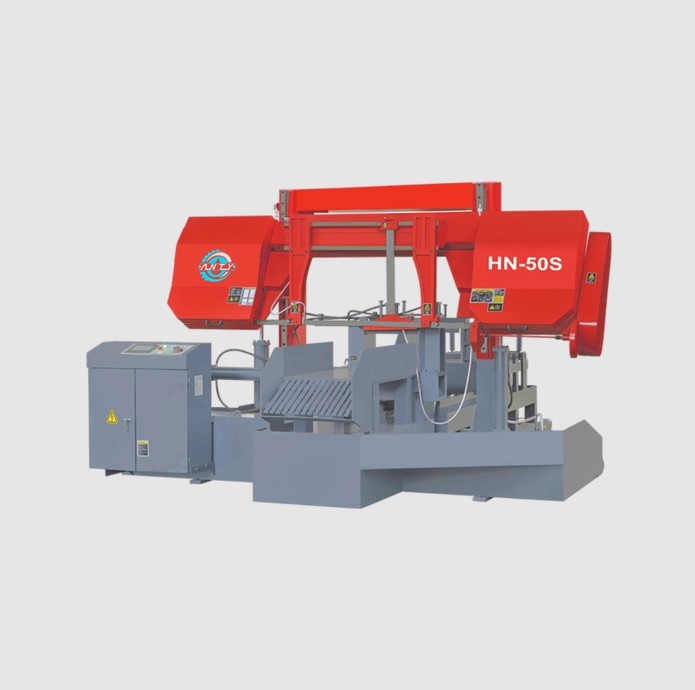

Horizontal Metal cutting Band sawing machine, Vertical metal band sawing machine are used across industries for precise cutting of metal components. The choice between horizontal and vertical machines depends on material size, shape, production volume, and cut type. Understanding their applications, safety measures, and operator training ensures effective and reliable operation.

Horizontal band saws are commonly used for repetitive cutting of long stock, bars, or tubing, providing stability and uniformity. Vertical band saws are better suited for irregular shapes, angled cuts, or smaller batch production. Each machine type requires different setup and handling techniques to achieve the desired accuracy and finish. Proper selection improves workflow efficiency and minimizes manual handling.

Safety measures are critical during operation. Band saws involve high-speed blades and sharp edges that can cause injury if proper precautions are not taken. Guards, proper clamping, protective equipment, and adherence to operating procedures reduce risk. Horizontal machines often have automated stops or sensors to detect misalignment, while vertical machines require operator awareness for manual adjustments and material handling.

Training operators on correct use, blade selection, and machine maintenance improves cutting accuracy and reduces wear. Understanding feed rate adjustments, blade tensioning, and cooling techniques is essential for producing consistent results. Operators also learn material preparation, clamping techniques, and routine maintenance practices to ensure long-term machine performance and reliable output.

Applications include industrial fabrication, automotive component production, construction materials, and custom workshop projects. Horizontal band saws provide efficiency for long or repetitive cuts, while vertical machines offer flexibility for complex or smaller components. Integrating both types into a workflow maximizes productivity while accommodating varied cutting requirements.

Proper combination of application knowledge, safety protocols, and operator training ensures that horizontal and vertical band sawing machines perform reliably. Consistent maintenance, careful material handling, and attention to operational details maintain precision and extend blade and machine life across diverse metalworking environments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness