Future Directions in Needle Design and Application

Special Medical Needles and Industrial Needles require careful design and production to meet safety, efficiency, and functional standards. While medical needles are essential for healthcare procedures, industrial needles serve diverse applications in manufacturing and textiles. Understanding the considerations for safety, customization, and design evolution highlights the importance of both types in their respective fields.

Safety Considerations for Medical and Industrial Needles

Safety is a primary concern for Special Medical Needles, which must be sterile, structurally sound, and precisely shaped to minimize patient discomfort. Quality checks include dimensional verification, tip sharpness assessment, and surface smoothness inspections. Packaging ensures that sterility is maintained until use. Proper handling guidelines, along with training, support safe operation and reduce the risk of injury or contamination.

Industrial needles also require safety measures, particularly in high-speed or automated processes. Needles must withstand repeated stress and maintain consistent dimensions to prevent machinery damage or product defects. Protective coatings, standardized sizes, and traceable production batches contribute to both operator safety and production reliability. Ensuring adherence to material and mechanical specifications is crucial to maintaining a safe work environment.

Customization and Specialized Needle Solutions

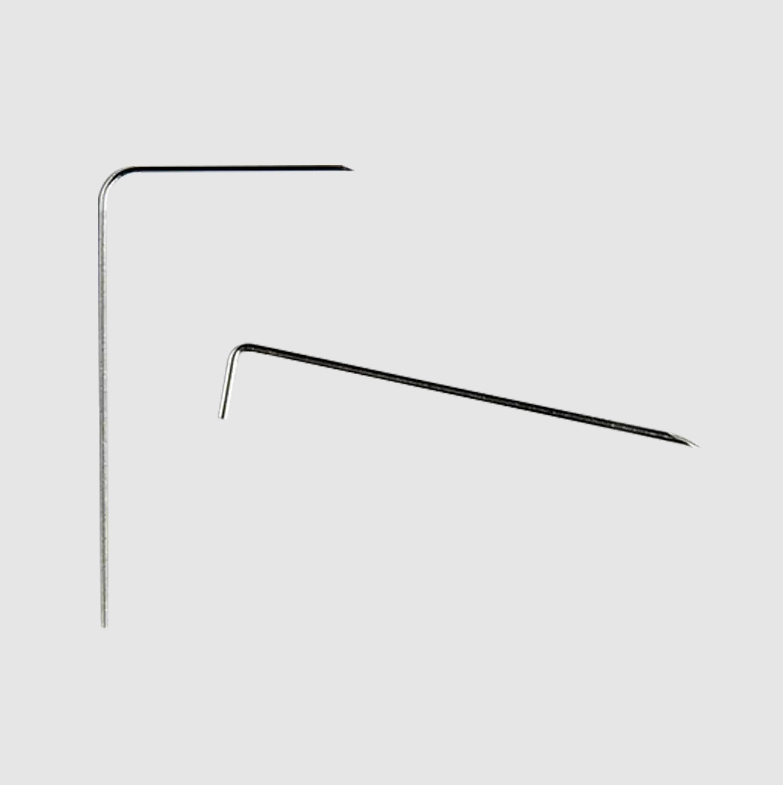

Customization plays an important role in both sectors. Medical needles are designed for specific procedures, such as spinal injections, biopsies, or catheter insertion, with variations in length, gauge, and tip type. Some needles incorporate coatings or specialized geometries to enhance patient comfort or procedure accuracy.

Industrial needles are tailored for diverse applications, including textile sewing, embroidery, injection molding, and electronics assembly. Material, hardness, tip shape, and coating are adjusted based on the specific manufacturing requirements. Modular or multifunctional designs allow faster integration into automated systems, improving operational efficiency without sacrificing quality.

Future Directions in Needle Design and Application

The evolution of needles continues to be shaped by technological advances. Medical needles are trending toward ultra-thin, flexible designs compatible with minimally invasive techniques. Surface treatments and coatings enhance performance and reduce friction. Automation in production and inspection ensures higher consistency and reliability.

Industrial needles are increasingly optimized for specialized tasks, offering greater durability, multifunctionality, and compatibility with high-speed machinery. Research in advanced alloys, hybrid materials, and coatings improves performance and reduces maintenance needs. As both medical and industrial applications evolve, design and engineering innovations will continue to enhance safety, functionality, and adaptability across all needle types.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness