How Metallic Processing Machinery Supports Automotive, Construction, and Industrial Sectors

Metallic processing machinery manufacturer plays a crucial role in the manufacturing industry, providing essential tools for shaping, cutting, and finishing metal products. These machines are used across various sectors to create components with precision and efficiency. From automotive parts to construction materials, metallic processing machinery is key to producing high-quality metal goods. Its applications span a wide range of industries, offering versatility and flexibility for different production needs.

Manufacturing Automotive Components

One of the primary applications of metallic processing machinery is in the automotive industry. Machinery such as CNC machines, lathes, and milling machines are used to produce a variety of components, including engine parts, transmission systems, and chassis frames. These machines allow manufacturers to achieve the tight tolerances required for automotive parts, ensuring reliability and safety. The precision of metallic processing machinery contributes to the overall performance of vehicles, making them essential tools for automotive production lines.

Fabricating Construction Materials

Metallic processing machinery is also widely used in the construction industry to fabricate materials such as steel beams, frames, and reinforcement bars. These machines are used to cut, shape, and assemble metal components that are then used in building structures, bridges, and infrastructure. With the ability to handle large, heavy materials, these machines help streamline the construction process, reducing the time and labor required to produce vital structural components.

Producing Precision Industrial Components

In addition to automotive and construction applications, metallic processing machinery is used extensively in the production of precision industrial components. This includes machinery for the manufacturing of gears, bearings, and tools used in a variety of industries like aerospace, defense, and electronics. The high level of accuracy offered by these machines ensures that parts function smoothly and reliably under demanding conditions, making them indispensable in sectors that require critical and high-performance components.

https://www.zjdfjx.cn/product/hydraulic-press-machinery/gantrylever-type-single-action-sheet-stretching-machine.html

https://www.zjdfjx.cn/product/hydraulic-press-machinery/gantrylever-type-single-action-sheet-stretching-machine.html

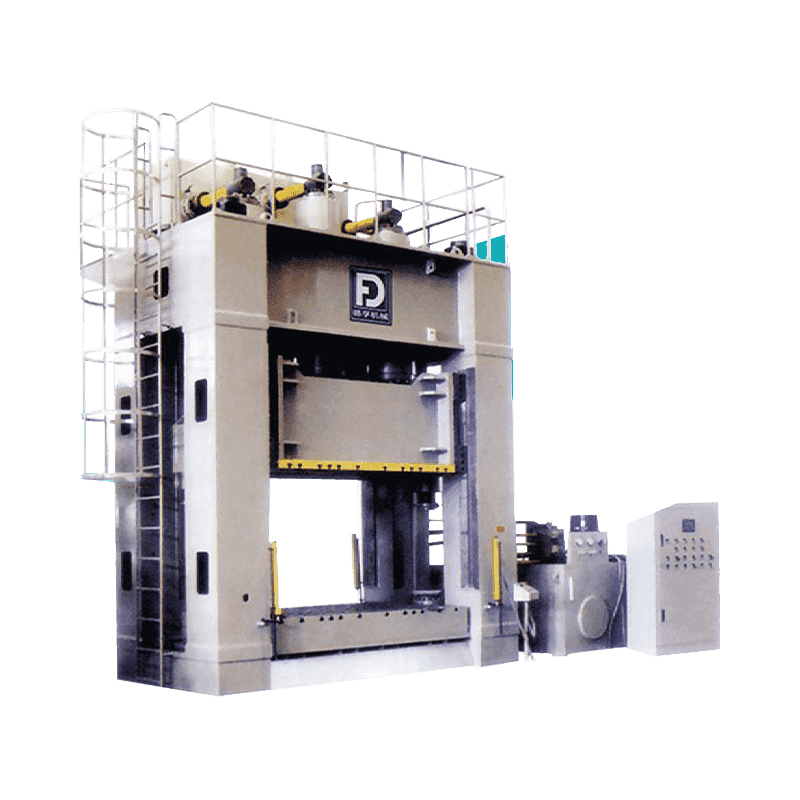

The Gantry Pull-Rod Single-Action Sheet Stretcher is a highly efficient and versatile machine that has revolutionized the manufacturing industry. This machine is designed to stretch sheets of metal or other materials into various shapes and sizes, making it ideal for a wide range of applications.

The Gantry Pull-Rod Single-Action Sheet Stretcher uses advanced technology to ensure precise control over the stretching process, resulting in consistent and accurate results every time. This means that manufacturers can produce large quantities of products quickly and easily, without sacrificing quality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness