How Textile Auxiliary Agent Supports Fabric Processing

Textile Auxiliary Agent refers to a wide range of chemicals used to support textile manufacturing at different stages. These agents improve process efficiency, fabric quality, and consistency by addressing challenges related to fiber variability and chemical interaction.

In pretreatment, wetting and scouring auxiliaries remove waxes, oils, and residues, preparing fabrics for uniform dye uptake. During dyeing, leveling and dispersing agents help distribute dyes evenly across fibers, reducing streaks and shade variation. These functions are essential for maintaining consistent appearance and performance.

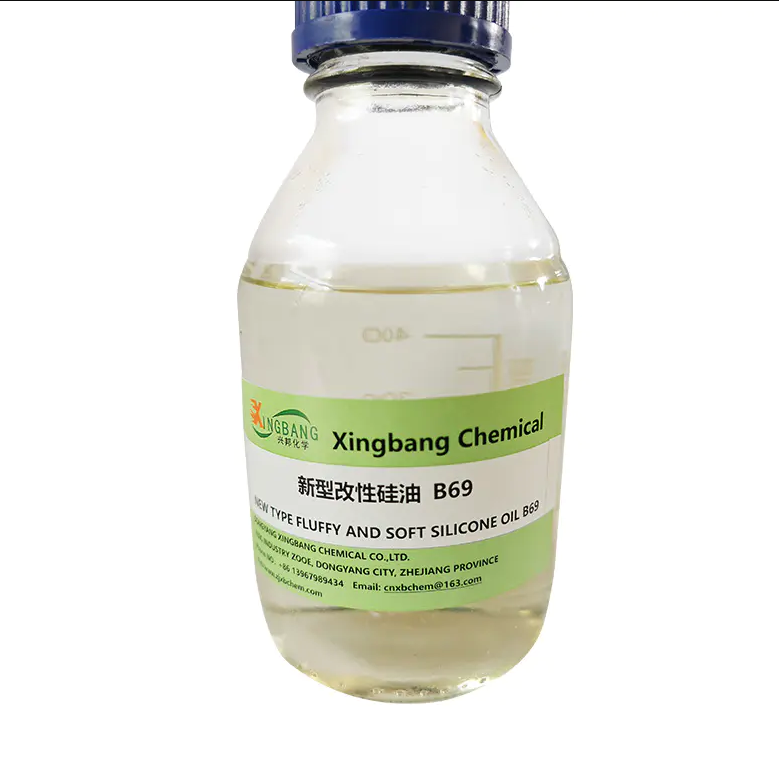

Finishing auxiliaries further enhance fabric properties. Softeners improve hand feel, antistatic agents reduce cling, and functional additives provide performance features such as moisture management or surface protection. Together, these agents allow manufacturers to tailor fabric characteristics to specific end uses.

By integrating textile auxiliary agents throughout production, mills achieve stable results while reducing inefficiencies. Many modern formulations are designed to support reduced water and energy consumption, aligning with sustainability goals.

Overall, Textile Auxiliary Agent plays a central role in supporting consistent textile production and dependable fabric quality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness